|

|

|

|

|

|

|

|

| 1.Development course |

|

|

|

| Treatment of organic waste water from chemical plants such as food processing field, has become mainly due to activated sludge method using aerobic microorganisms from conventional. In recent years, technology development to achieve a reduction of the cost in the compact has been promoted, technology development averaging of water quality and anti-corruption in the raw water relates to a high efficiency of the process in the microbial treatment tank for many years when they met in the it has been advanced through, you do not see the realm of complete still. As one of the measures, there is improvement of the aerator (air diffuser). Thing of bubble generation type using porous material, porous plate, and movable plate, clogging of the pores and deposition of sludge generated by the driving operation conditions and installation location. Causing a vortex flow by a large excess of energy is needed to prevent this. However, this method is wasteful of energy. In order to solve these problems, without causing deposition of sludge and clogging, aerator capable of operating in the energy conservation is desired. |

|

| Therefore, in our company, aerator new method of pentagonal and, in the

air-lift method: I was originally developed in 2006 (2006) (trade name

Kukai). Construction of new wastewater treatment facilities as well, such

as the reduction of the cost clogging improvement of the bubble discharge

portion of the bubble generation-type aerator, sludge deposition improvement

in the tank, by the air reduction, the improvement of the failure of the

aerator of other types of I have responded to inquiries for the purpose.

And, it was aimed at improved further improvement of our aerator to meet

adequately the needs of these. The contents of technological development,

installation of opening to the strut is fixed to the bottom of the tank

aerator, a change in the main body tube height, adjust the clearance between

the tube end and the lower bottom of the tank, change the installation

position of the outlet of the air piping the conduct, etc., and was observed

by visualization aquarium liquidity situation of (beads as simulated sludge)

sludge of the bottom of the tank, were optimized, 2011 to (of 2011) each

structure (Foundation Kagawa industry Support Foundation which was developed

by the "2011 fiscal Kagawa SME support fund business challenge new

fields support project"). |

|

|

|

|

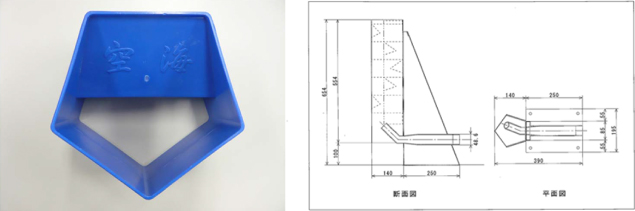

| The aerator Company, in which the waste water and solids or gases are mixed,

was developed with a view to efficiently dissolution of oxygen to the wastewater

as well as complete mixing of the substance, top and bottom of the pentagon

in the same area the invention has been constructed in a state of placing

the cylinder in multiple stages in the vertical direction (Figure 1) impingement

plate having an opening, having a clearance between the cylindrical portion

and the gas ejection nozzle, the location bottom to the tube bottom there

(Figure 2). |

|

|

|

| Appearance of Figure 1 collision plate Schematic

diagram of Figure 2 aerator |

|

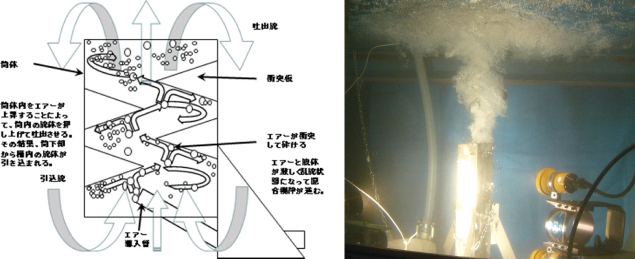

| Figure 3 The effect of the aerator shown in Figure 4 the discharge status

of actual air. It rises the cylindrical body while colliding with the collision

plate, the liquid and then pumping due to the increase of the gas in the

cylinder, the gas ejected from the gas-liquid jet nozzle in the waste water

can be entrained in the pumping such as solid to enter the tubular body

from internal clearance part of the cylinder bottom. As a result, the three

parties to complete mixing liquid, gas, solid coexist in the cylindrical

body inside, gas along with the finer by the effect of collision plate.

|

|

|

|

| Situation of the gas-liquidmixing inFigure 3 aeratorinternal Discharge situation of Figure 4 air |

|

| If a collision plate shown in Fig 1 is a shape close to a circle, because the fluid flows along the circumference, turbulent flow in the circumferential direction is less likely to occur. If you have polygonal, turbulence is likely to occur in order to proceed with flow impinges on each side. On the other hand, the flow itself in the circumferential direction is not generated resistance is too large when you square such as a triangle, the flow is short-circuited only upward. Pentagon has been determined as the optimum shape as a result. Moreover, results of a study in consideration of the flow in the vertical direction for the number of stages of the impingement plate, the optimum number of stages was determined in five stages. |

|

|

|

2.2 The presence or absence of patent |

|

|

(1) the rights of -220 164 gas-liquid mixing device

No. 5016052 discloses Kukai Patent Registration

No. 2006 No. 4,907,258 discloses a gas-liquid mixing device trademark registration

tracheal collision plate patent registration diffuser

No. 1,304,967 discloses impingement trachea design registration diffuser

No. 1,304,966 discloses impingement those design registration that are

|

|

(2) pending Schedule

16.05. Those 2006 PCT / JP2006 / 309694 gas-liquid mixing device |

|

(3) Future

It is expected that you are considering what you depending on a variety

of applications, optimized by improving the material, surface Seijo, and

other mechanisms, to promote the rights of each. |

|

|

|

|

|

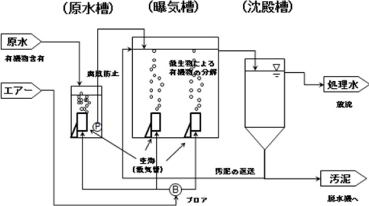

| As an example of our performance, frozen food processing plants in (wastewater

Date amount 100m 3), shown in Figure 5 schematically an example of (2 units

in the raw water tank, six installed in the aeration tank) was installed

aerator. This is what was using the air diffuser of porous type that generates

fine bubbles in the wastewater treatment facility of the frozen food processing

plants but worked for the purpose of performance improvement. I was shown

in Table 1 provides an overview of the operation result. That the processing

performance is maintained even after a lapse of 1 year quality is improved

and our aerator after introduction was confirmed. Power usage for one week

average of aerator when using porous type was 1,320kWh, but the power reduction

1,075kWh next, about 19% was achieved in the new aerator after the introduction. |

|

|

|

| Installation situation of Figure 5 aerator |

|

|

|

| One case of driving the results in Table 1 aerator |

|

|

|

|

|

| Selection criteria of the aerator in wastewater treatment facilities is

as follows. In the raw water tank, main purpose is homogenization of water

quality and anti-corruption due to residence and settling of solids. Therefore,

it is considered preferentially the stirring effect due to the suction

of the fluid due to the air-lift effect of the bottom aerators. Design

criteria are (capable of sucking area of the fluid) responsible area per

unit. In the aeration tank, the primary objective is the provision of adequate

oxygen to activated sludge. Design criteria is (2-17% depending on the

depth) of the oxygen dissolution efficiency. We aerator, may be a design

criteria for each of the dissolution efficiency of oxygen and agitation

capabilities as can be seen from these results. For reference, in the aeration

tank of the application of the activated sludge methods generally shown

in FIG comparison when using the aerator our porous type which generates

fine bubbles. |

|

|

|

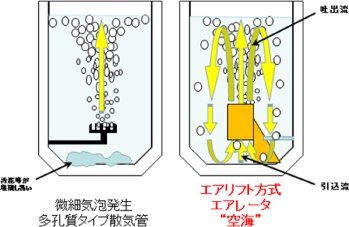

| Sludge deposition effect of preventing our 6 aerator Figure |

|

Those of a porous type prone deposition of sludge in the aerator bottom because there is no air lift effect. It can be said, prevent problems such as deposition of sludge, and exhibits stable performance in the long term, maintenance is the easy our aerator to it. For example, there is no clogging even current first Unit installed at the wastewater treatment facility of food processing plants in Nagano Prefecture, 2006 (2006), it is stable and running.

Since By causing convection continuously aeration tank, preventing the deposition of sludge in the aerator body, no clogging, is considered to be unnecessary maintenance (aerator) basically. The difference between a porous type, intermittent operation is possible because the opening is large. Thing of the fine bubble generation type, it becomes negative pressure When you stop the supply of oxygen, clogging occurs instantaneously. Even though the state of over-aeration, then, with it possible to stop the free supply of oxygen, our aerator, so can cope with increase in the amount of air it can be used in any processing plant (the diameter of the pipe: 40A / KA-L type). |

|

|

|

|

|

As is also shown in 2.1-2.4 described above, first it is placed in (2006

sustained stable performance .

No clogging, even today Unit), power reduction (about 19% is achieved reduction

of energy use), maintenance .

I can be achieved, such as ease of management. In before and after the introduction of our aerator, yes in some food processing plants

Was able to reduce 40% of water treatment costs. I would like to note here is the individual data such as dissolution efficiency of oxygen

It is about making a comparison. Aerator smell of porous types that occur in the micro-bubbles

The Te, some higher value than the diffusing pipe our Compared to the only dissolution efficiency of oxygen, but before

Originally, aerator is necessary to consider the dissolution efficiency

of oxygen along with the agitation of the wastewater, as shown in predicates

.

There. Aerator Our value as an indicator of Der having both at the same time the dissolution of oxygen and stirring effect

That |

|

|

|

|

|

I show based on past achievements, the scope of the new diffuser tubes related to the processing of organic waste water. Food

In addition to the processing plants, livestock farms, slaughterhouses, dyeing factory, agricultural settlements, and joint kitchen, is applied to a wide variety of

Have been. In particular, our diffusing pipe is highly evaluated from tofu industry, it has been featured in industry magazines. Its

And then improved since 2011 (of 2011), aeration tube of improved type are sold steadily, the present time

It is more than 300 units total to be, including those under negotiation in point. It is worth noting above all, real previous

As shown in the example introduced, most of the inquiries by generating fine bubbles in the waste water treatment facility

Had been using the air diffuser of porous type that although running costs and the (anti-clogging performance improvement

It is that it is one that worked for the purpose of reducing) bet.

Also not aerator currently, was both a stirring force and dissolution efficiency of oxygen at home and abroad, well as some other German

There is an inquiry from overseas companies such as France and Canada, have also considering expansion into overseas

That

Trouble such as a failure of the propeller is a concern with mechanical agitation, but due to agitation using a gas with simple structure, used in the production line as well as wastewater treatment is also expected in the future |

|

|

|

|

|

As can be seen from the demand of the customers of installation as an alternative to the type design patents and originality variety is registered, has been generally so far, originality of our aerator has already been demonstrated I believe that. One such pressure loss is small compared to that of the porous type. Piping is installed in the lower cylinder, air bubbles are ejected into the tube interior. It is very efficient because there is no point where pressure is applied. In addition, the dissolution efficiency of oxygen is higher the water depth is deep aerator so far. Dissolution efficiency resulting in decreased water depth is shallow in reverse. In our aerator, each is miniaturized by the liquid, gaseous, solid is stirred at collision plate disposed inside the cylinder, dissolution efficiency is increased. That water depth that can operate as long 1m or more are also a feature.

Countermeasures against the regulations of 2.8 future

To the demands on the reduction of costs and improvement of water quality, correspondence is possible |

|

|

|

2.8 Countermeasures against future regulations |

|

|

| To the demands on the reduction of costs and improvement of water quality,

correspondence is possible |

|

| 3.Field of application |

|

|

|

To supply other than the oxygen in the activated sludge process, the query is increasing also stirring in the anaerobic tank such as denitrification. Corresponding to the intermittent operation of the driving operation is also required. For example, intermittent operation of the equipment is required if the amount of wastewater is not stable due to the preparation of the production volume of products in food processing plants. Failure pores that obstruction during stop in diffusing tube of fine pores of the conventional type had frequently but diffusing pipe of the new development is not blocked for the opening is large. Cited in the manufacture process has increased the wastewater treatment other than recently. For example, stirring and mixing in oxygen-free conditions of food materials ①, ② ionization of chemical raw materials, and the like cooling, the fluid ③. Method of operating aeration tube in the operating conditions as well, and started a new study also material in any case. Various development shall have all stainless steel, corrosion-resistant, the finish of sanitary format, all-plastic, such as those having a special surface shape other is in progress.

It should be noted that the inquiry has been inundated with companies from more than 10 companies to date |

|

|

|

|

|

|

|

|